Capstone

Senior Design (Capstone) Project

Final Solidworks Assembly

Design

My group’s capstone project was to design a rear suspension system for a formula society of automotive engineers (SAE) car. The FSAE student organization was creating their first vehicle and outsourced some of the subsystems to capstone groups. Since this was the very first vehicle the team was looking to create, we had to design a system with the only known variables being the chassis size and material. The largest factors that came into play were communication and integration of our system with related (and generally nonexistent) systems of the car. In the end, we designed a suspension for the team and purchased most of the components. However it would need to be assembled at a later date when the rest of the car was built.

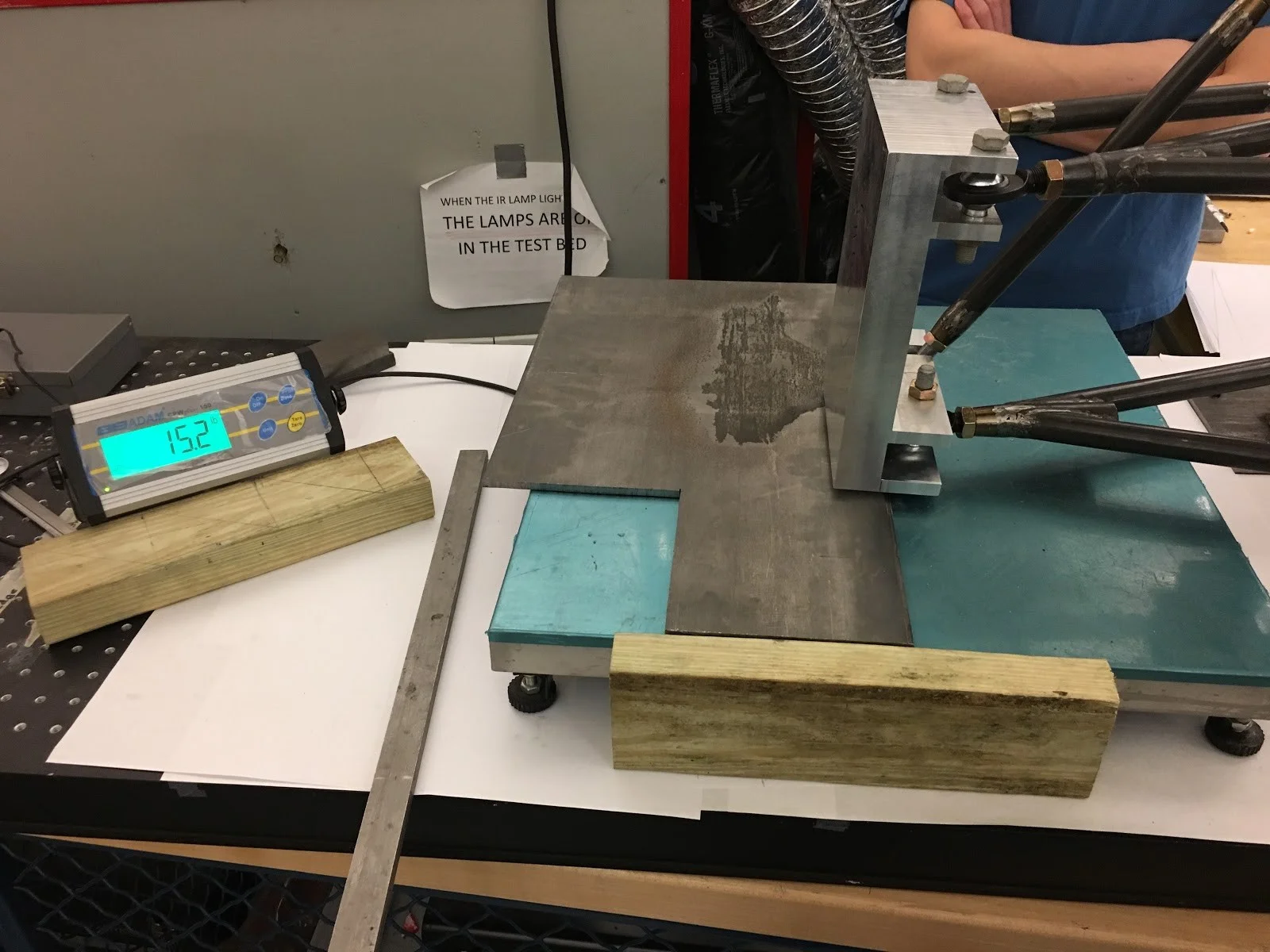

Test build

Testing

Physical tested was limited as we did not have the resources to accurately model the dynamic situation that the vehicle would experience. We ran theoretical static and dynamic tests via software to determine various loads and responses. The physical testing we were able to do was to verify and model the structural layout of the design so that it could be presented as a system. Some subsystems such as the spring and damper system were purchased, however the overall assembly was machined and welded in house.

Testing load ratios

Experience gained

Team leadership and organization

Long term project oversight and presentation

Machining and welding experience

Test method development and adjustment

FEA analysis